When concrete fails

An interview with Dr. Guy Keulemans on ‘the problem with reinforced concrete’

We are a ways off from understanding what caused the June 24 collapse of the Champlain Towers South building outside Miami. We know that in 2018 an engineer found spalling concrete, rusting exposed rebar, and standing puddles of water in the basement parking garage, which were ominous but not definitive signs of an imminent failure.1

Watching video footage of the collapse and thinking about the people who were caught off guard in their homes, I felt a hellish vertigo. Most days we take it for granted that the floor will hold. We might even feel some extra confidence in the case of reinforced concrete, an extremely common construction material with steel rods laid through it to add tensile strength.

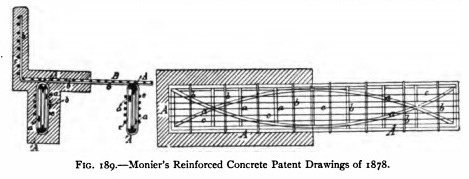

Reinforced concrete revolutionized modern architecture by allowing relatively inexpensive, apparently durable construction. Starting in the late 19th century, we built taller skyscrapers and daring cantilevered forms, increasingly confident in a technology that seemed more solid than a rock.

There has been a reassessment in recent years. Particularly as climate change exposes buildings to new temperature and moisture extremes, new concrete structures can begin to deteriorate in 10 to 20 years if proper precautions are not taken. And concrete is not doing many favors for the environment either: Its manufacture generates 5% of global CO2 emissions, and its demolition generates one-third of all landfill waste.

I started thinking critically about concrete this week, in the aftermath of the Champlain Towers collapse, when someone in my circle shared an article by Dr. Guy Keulemans.

Keulemans is a lecturer in the School of Art & Design at UNSW Australia, and he wrote a piece for The Conversation in 2016 called “The problem with reinforced concrete.” It’s a provocative article, maybe even a little contrarian, and I learned a lot as I read it. After checking out more of Dr. Keulemans’ work via his website, I emailed him some questions. Our conversation is below.

Brutal South: One surprising thing I've learned from your work is that steel-reinforced concrete can be volatile and impermanent. To a layman like me, it sounds like something that would last for centuries, but that's turning out not to be the case. When building with reinforced concrete, what are some of the biggest risk factors?

Dr. Guy Keulemans: This is an example of how we can’t trust our most immediate perceptions when it comes to materials. Especially for building, in which materials are layered in structural applications intended to last well beyond a human lifetime (hopefully). Tradition is one mechanism in which material capacities can be assessed across generations, but in the 19th and 20th century this was replaced by increasingly advanced methods of engineering and manufacturing that could make design applications thinner, lighter or otherwise much closer to their failure points without necessarily passing their failure points — at least in the short term. This is true for other areas of material design, not just construction, but product design too. Planned obsolescence isn’t really planned, no engineer really wants a product to fail or break generally speaking, but it is the consequence of economic constraints and engineering decisions to make products or structures cheaper, lighter and even more efficient, in aspects not relating to durability.

Specifically for steel-reinforced concrete, it’s a theoretically imperfect material composite, but a practically sufficient one. A “monstrous hybrid,” I would say, a term from William McDonough and Michael Braungart, the authors of Cradle to Cradle, a circular economy theory. Steel is corrosively reactive to moisture but this can be minimised or even avoided by human maintenance. Concrete is permeable to moisture but physically restricts maintenance of anything inside it. Hence steel-reinforced concrete is inherently obsolescent. From my perspective as a sustainability researcher, this trumps all other reasons for the composite, no matter how much construction engineers argue for its other composite qualities.

BS: In your piece for The Conversation (“The problem with reinforced concrete”) a few years ago, you mentioned some ideas like cathodic rust protection and some alternatives to steel rebar — stainless steel, aluminum bronze, and fiber-polymer composites — but you wrote at the time that those were not widely used because steel rebar is cheaper. What can be done to change industry practices? Is it a matter of fighting for building codes at the local level? Is there any energy behind changing the industry at a national or international level?

GK: I think most countries use national guidelines to set or steer state and local building codes. International trade agreements or legal frameworks like the EU use could also be used to influence change. But like other industries, such regulations are set in consultation with industry, who have lobbying power, so environmentally sound practices are not being implemented fast enough. In the case of glu-lam composite timber building — one of the key game-changing building technologies that can replace steel-reinforced concrete — building codes have actively worked against change. The Tallwood Residence in Vancouver was designed with a central reinforced concrete lift well core in order for it to obtain construction approval, though it could have been built with glu-lam timber alone. But I am always impressed by those architects that bring their clients into sustainable design and then fight to apply better technologies as best they can. It’s tough work, but they shine the light for the construction industry to follow.

BS: Concrete in one form or another has been used for millennia, but modernist architects and builders seemed to latch onto it in a utopian sort of way in the 20th century. I read Kenneth Frampton's Modern Architecture last year, and I highlighted this passage about Le Corbusier's time working for the reinforced-concrete pioneer Auguste Perret in Paris in 1908:

[H]e became convinced through his contact with Perret, that béton armé was the material of the future. Aside from its malleable monolithic nature, its durability and inherent economy, Perret valued the concrete frame as an agent for resolving the age-old conflict between the structural authenticity of the Gothic and the Humanist values of Classical form.

Reinforced concrete helped him resolve some aesthetic problems he was working on, but the kind of throwaway clause from that sentence — "its durability and inherent economy" — turns out to have been a little naive. What do you make of the modernists' fascination with concrete? Were they blinded to warning signs, or were they working with the best scientific knowledge at their disposal at the time?

GK: Robert Courland in his Concrete Planet book discusses this at length. My memory of that discussion is that it was a combination of not really knowing (after all, it still took quite a few decades for the first buildings to fail), plus their faith in the engineering calculations and its strong appearance. But, importantly too, there is evidence that the concrete industry itself covered up durability problems in the 20th century in order to expand their market. The tragedy of this is that the ubiquity of reinforced concrete construction has displaced more sustainable building technologies — masonry, brick, rammed earth and mudbrick, etc. Some traditional techniques in the developing world may even be lost for good.

So the 20th century architects were wrong about durability, thinking that it would last a thousand years or more like some Roman concrete structures, but they weren’t wrong about its inherent economy. Like so many things, the cost and carbon impact of future rebuilding is not measured in the current economic paradigm. Why would a developer care if a building fails in 50 or 80 years? They’ll be dead by then. So it’s an issue for civilisation to manage over long time scales. The hardest thing that sustainability researchers do is develop new tools that can be reliably used to measure the value of externalities in the present and future — not just the cost of rebuilding in simple financial terms, but the cost of rebuilding in extended financial terms that include aspects of ecological impact and social justice. Intergenerational equity too. It’s tremendously depressing that my children or grandchildren will have to pay to replace buildings that could have been built to last longer with just a little more expense. This rebuilding contributes to climate change too. But there is room to calculate and absorb the costs of reducing such future harms and impacts, by building better in the present, because the construction industry is so immensely profitable.

BS: So now we have untold tons of concrete buildings and bridges on the earth, and it's not always efficient or cost-effective to knock them down, salvage the rebar, and recycle the concrete. Particularly as climate change takes its toll with new temperature extremes and moisture incursion in coastal areas, what can be done to shore up and repair the infrastructure we decide to keep?

GK: That’s an important question and not one easy to answer. Steel reinforced concrete is not easy to repair and not easy to recycle.

Regarding repair, there are a bunch of stop-gap measures to slow down the decay, but if someone wants a building properly restored, like they’ve done for Frank Lloyd’s Unity Temple … well, it’s crazy. You have to scrape off one side of the concrete, propping up the structure internally so it doesn’t collapse, pull out and replace the rebar, reapply concrete, then repeat the process from the other side. Basically the whole building is replaced, costing more than initial construction even after adjusting for inflation. That’s not going to happen for the vast majority of buildings.

Regarding reuse, for my part I am exploring better ways to identify, sort and transform construction waste into new products at a studio level, but I’m starting with more inherently suitable materials for reuse, like timber. Even perfectly good timber gets chucked into landfill. I want to explore the harder problems at some point but what can you really do with rebar and broken concrete? That’s a perplexing design challenge. The most obvious thing with rebar is to melt it down and recycle it into better building technologies, but that’s not energy efficient. Secondhand concrete isn’t really good for anything I know about yet. I don’t even think it can be easily used as aggregate in new concrete structures because its unknown chemical composition unpredictably weakens the mix, though I’d love to be proven wrong on that point.

BS: I loved one of the pieces of artwork that you and Kyoko Hashimoto created, the string of Buddhist prayer beads made of concrete balls with rebar jutting out. In your artist statement you wrote how the piece is designed to crack and crumble over time, just like the concrete in buildings. You also had some harsh words for the concrete industry — so harsh that they declined to print the statement in the exhibit catalog. How does polemical art like this fit into your research? What utility do you think it has?

GK: Kyoko and I work within the field of critical design — we use design to critique the discipline of design. In doing so I hope to make some of the key issues of sustainability tangible to people both inside and outside design. You can think of my work as prototypes but in some respects they are props, or three-dimensional illustrations of a problem or a system. More poetic than a diagram, more explicit than an artwork.

Obviously if we want change we cannot be afraid to speak truth to power. The concrete industry in Australia is appallingly awful. Not just for perpetuating unsustainable building in place of better alternatives, but by actively working against the use of more sustainable materials, using environmentally harmful supply chains and through bad corporate citizenship like price fixing and tax avoidance. And don’t get me started on sand piracy.

The article was commissioned to be a complementary text to the designwork you mention. It was a curatorial decision not to publish that text in the catalogue, but I understand the decision because the concrete industry was funding the exhibition. So on one hand it might be greenwashing, but on the other hand the design and craft studio industry in Australia is financially precarious. I published the article anyway (on Medium) and our designwork was still included in the touring exhibition (CONCRETE: art design architecture), so the critique is still present and in other respects it’s an excellent exhibition.

BS: OK, here is a shallow question: I love brutalist architecture on an aesthetic level. What do you think of brutalism, and what should be done with brutalist buildings?

GK: I guess like any style of architecture there are good and bad examples. There is a great example in my city of Sydney, the Sirius building, designed by Tao Gofers and built as public housing in the 1970s. It has views of the Opera House and Sydney Harbour Bridge and was nearly torn down a few years ago. Heritage and social housing activists managed to save it from destruction but then its tenants were evicted and the building renovated into luxury apartments just recently. I threw up in my mouth a little bit when I saw the real estate spreads in the paper last month.

***

Brutal South publishes for free on Wednesdays. To support my work, read some subscriber-only issues, and get some cool vinyl stickers in the mail, please consider signing up as a paid subscriber at $5 a month.

Over the weekend I published an interview with the disgraced death penalty engineer Fred A. Leuchter Jr. in the Welcome to Hell World newsletter. You can read an excerpt in Brutal South. Since the interview ran, I have filed a Freedom of Information Act request with the South Carolina Department of Corrections seeking information about the provenance, maintenance, and inspection of its electrocution equipment. I will keep you posted on what I find.

Twitter // Bookshop // Bandcamp // Apple Podcasts // Spotify Podcasts

I’ve read several credible theories in the Miami Herald and New York Times. It could have been a sinkhole, poor-quality building materials, improperly installed piles, an improperly sloped pool deck, or persistent water damage from a leaky pool or ocean water — or some combination of the above, or none of the above. I’m not qualified to diagnose what happened, and I’m not going to try.